The resistance of fixings depends largely on the properties of the substrate. Since they are not always known in construction projects, job site tests give some indication whether an anchor is suitable for a respective substrate. Using a mobile pull-out system, the characteristic resistance of a plastic anchor can be determined on the construction site.

In the European markets, manufacturers and users rely on construction products that have ETA (European Technical Assessment) approval. The ETA provides information on the amount of the pulling force absorbed by an anchor in a specific substrate. These forces are reflected in the characteristic resistance and based on lab tests that are carried out by certified testing laboratories. Due to the enormous diversity of substrates and constant new developments, not all types of substrates can be incorporated in an approval.

Especially when it comes to the masonry, the wide range does not allow for a general categorization. As bricks differ by structure (solid brick, perforated brick) and material (clay brick, lime-sand brick, lightweight concrete, autoclaved aerated concrete), the bulk density of bricks and hence their compressive strength vary. The compressive strength has a significant impact on the anchor retention force in the substrate.

The characteristic resistances given in the ETAs for use in hollow or perforated masonry are valid for the bricks and blocks only which have been used in the tests regarding base material, size of the units, compressive strength and configuration of the voids.

Source: ETAG 020 – Annex B

When a construction site project requires anchors to be fixed in a substrate that is unknown or not shown in the ETA, job site tests or so-called anchor pull-out tests must be carried out. Another reason for these tests can be the desire to change the drilling method or anchoring depth. Accordingly, job site tests must always be done when deviations from the approval take place in practice. They ensure whether the anchor in the respective substrate achieves the characteristic resistance.

Recording tests in test report

The resistance of the anchor must be determined by pull-out tests on the construction works. A minimum of 15 test values must be recorded in a test report. The report should contain all information that is required to assess the resistance of the tested plastic anchors.

The tests are to be carried out as described in ETAG 020 Annex C. The anchor is correctly anchored when after the screw is fully inserted, neither the anchor sleeve can rotate nor a slight further rotation of the screw is possible. Tip: In the case of a critical substrate, a cordless drill using a slip clutch helps to limit the anchor screw’s insertion torque. (Technical article: Optimum use of cordless drills)

After an anchor has been anchored in accordance with the instructions of the manufacturer, a pull-out device is used to exert a controlled, continuous load increase on the anchor. The centric tension load should be increased steadily so that the ultimate load is achieved after about 1 minute. Upon achieving the ultimate load, the load is recorded in the test report.

After 15 pull-out tests, the load class evaluation takes places. The evaluation requires the following procedure:

- Select the five smallest values from the 15 job site tests

- Determine the mean value of these five values. This value is denoted as N1

- Multiply N1 by 0.5 to obtain the characteristic resistance of the anchor (NRk1). This value is comparable to the approval values FRk,ETA

- Divide NRk1 by the partial safety factor ƴM to obtain the anchor load class. ƴM depends on the substrate (e.g. masonry: ƴM = 2.5).

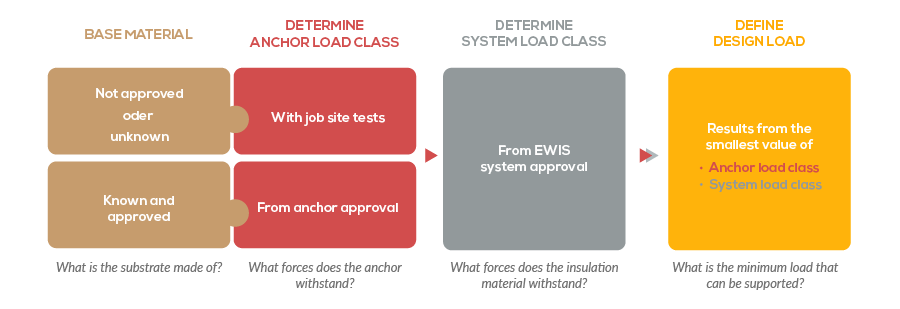

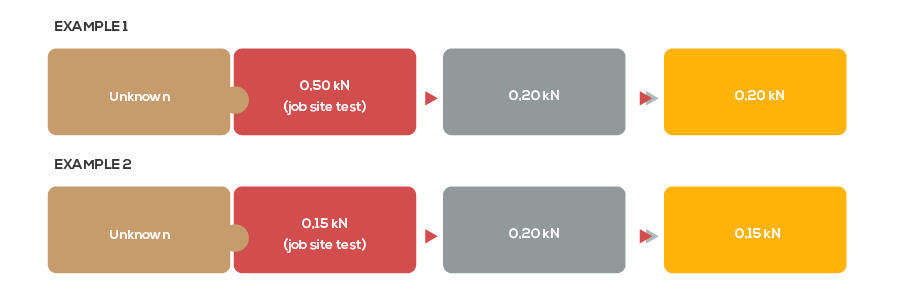

The anchor load class equals the design load if it is smaller than the system load class. However, if the anchor load class is higher than the system load class, the system load class is used as the design load.

What can be done to improve anchor retention force and hence anchor load class?

- Changing the drilling method: rotary drilling instead of hammer drilling

- Increasing the anchoring depth by a minimum of 2 cm

The drilling method and/or anchoring depth selected for the tests must later be used for the construction. If the adaptations fail to result in a load class increase, as an alternative, a different anchor can be used.

The design load will then serve as the basis to calculate the number of anchors. Roughly speaking, the required number of anchors per square metre is determined by the relation between design load and wind load. However, in order to arrive at the concrete number, additional parameters must be taken into account which may partially influence each other. Therefore, for every project, the required number of anchors should always be calculated by the system supplier or a relevant planning firm (Technical article: Dowels per square metre: Saving on the wrong things).

Do you need help in the planning or carrying out of anchor pull-out tests? Contact us for more information or an appointment.