We all want to feel comfy and cosy at home. Apart from the right thermal insulation, sound insulation is equally important when it comes to our wellbeing at home. Soundproofing is therefore an important feature of any quality home. Purely mechanically fastened insulation boards will have a positive impact on keeping sound out.

Our cities are full of noise-generating sources which are steadily increasing not only in metropolitan areas. Alongside a growing number of cars and airplanes, other sources such as industry or our own neighbourhood add to noise pollution. But how do you define noise? Noise is any sound the human ear perceives as disruptive. To avoid noise, we need measures to reduce sound transmission. In the last few decades, soundproofing has gained importance. In this context, the position of source and receiver is as decisive as are the components and how they are fixed, because sound can travel in a variety of ways.

Sound travels in mechanical waves and pressure waves. The pressure waves are created by mechanical vibration, impact sound or airborne sound. The latter is interesting when it comes to the selection of construction materials for facades because: the thicker a wall, the better the sound insulation. However, mass and density of parts and components are much more significant. Leaks reduce sound insulation critically, which becomes highly evident when you compare unrendered facades with rendered ones. Massive materials such as lime-sand brick have a soundproofing advantage over less massive hollow blocks of the same thickness.

Soundproofing is strongly influenced by the construction of ETICS

At the same time, the construction of building materials is as crucial as their properties. Type and thickness of the insulating material and the adhesive used for the insulation boards play a major role in ETICS facades. If, for example, the external thermal insulation composite system is constructed by rigid boards, the entire layer of wall, adhesive, insulation material and render acts as a single-leaf solid wall that lacks the necessary spring function. Therefore, flexible insulation boards together with two-leaf constructions in general have proven suitable in insulating sound. The distance between the two leaves allows for air to get trapped. This way, only a small amount of sound energy is transferred by the spring.

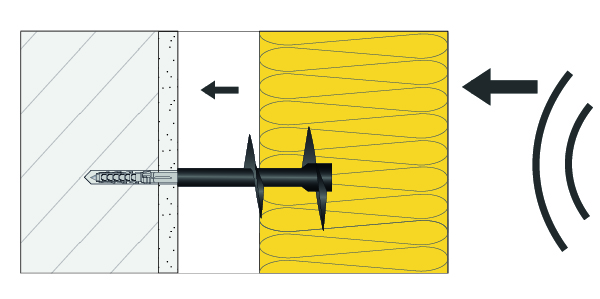

The Stellfuchs system utilizes this physical effect. By enabling the fastening of insulation boards to a distance of up to 70mm, a layer of air is generated.