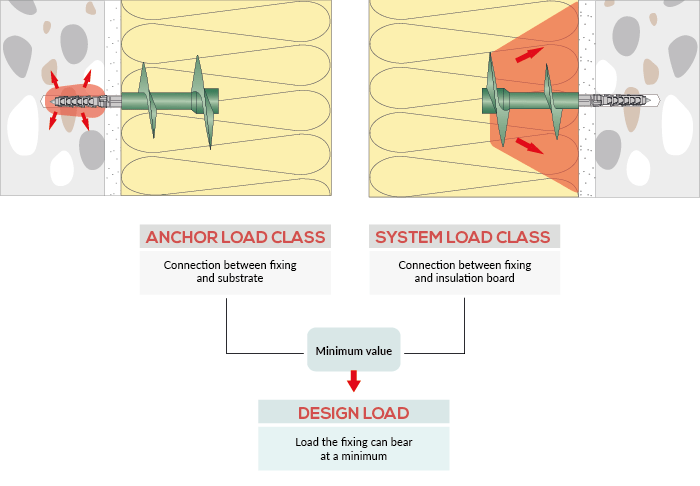

An ETICS fixing has the task of holding insulating materials securely to the facade. How effectively a fixing performs can be determined by anchor load and system load class. The latter provides information on how much load the fixing can carry from the insulation board

An ETIC system combines several building materials into one system. The advantage of this is obvious: the building materials are deliberately combined by experts and tested as a bundle against external influences, such as wind. The system holder guarantees its promise to provide a functional system.

To make sure that the fixing fits the respective system, it is examined from several sides. On the one hand, the system load is determined during tests. This value describes the characteristic load-bearing capacity of the fixing in the insulation board or how good the connection between the fixing and the insulation board is. More precisely, the system load class indicates the overlay forces that the fixing plate can withstand.

In addition, the anchor load class is relevant. It defines the characteristic load-bearing capacity in the substrate and thus how much load the fixing can transfer to the substrate (technical article: Determining anchor resistances with job site tests).

The smaller of the anchor load class and the system load class gives the design load of a composite thermal insulation system. It indicates the minimum force that a fixing can absorb and thus takes into account the connection between the fixing and the substrate as well as the connection between the fixing and the insulation material. This makes the value an important factor for the safety of a composite thermal insulation system.

Various tests determine the system load

The system load class is determined during tests in testing institutes. In order to determine the load-bearing capacity of the fixing in the insulation board, the tester has various methods at his disposal. In the pull-through test a single fixing is pulled through a block of insulation material. Wind suction is simulated by the building load acting on the dowel.

In the foam block test, the tester proceeds in the same technical manner, but with several dowels per insulation board. This method addresses the fact that an increasing number of dowels per insulation board can have a negative effect on the holding values.

The combined test examines the ETIC system as a holistic unit. In addition to the wind load, the dead load of the system is determined, which the fixings can absorb at maximum.

Although the ETA provides uniform approval in Europe, there are no guidelines or specifications on the test procedure for determining the system load. At present, each country decides independently. Even nationally, for example in Germany, experts discuss the verification format, i.e. which method should be used as standard in the future.